Highway guardrail roll forming line

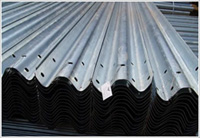

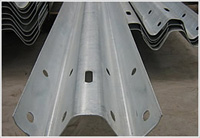

Description of W-beam guardrails:

Description of W-beam guardrails:

W-beam guardrails are cost-effective longitudinal highway barriers designed to reduce the severity of run-off-road (ROR) collisions, prevent vehicular impact with roadside objects, and lessen the likelihood of vehicle overturning.

W-beam highway guardrails are the most common crash barrier used on Chinese highways due to their high effectiveness and inexpensive production costs.

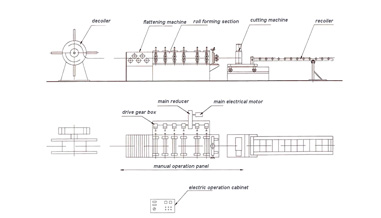

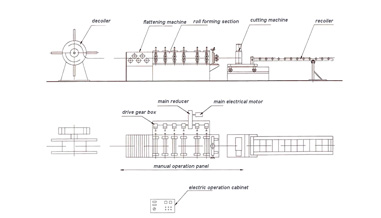

Layout of guardrail rollformer:

Roll forming process for W-beam guardrail:

Two-head decoiler----11 roller straightening machine-----four pillar hydraulic punching & shearing machine----feeding mahine----12 passages forming machine----recoiler----collecting table----electrical cabinet

Technical parameters of two waves guardrail roll forming line:

1.Two head decoiler

Loading weight: 10T; Inner diameter: 550mm; Motor power: 7.5kw; Overall dimension: 2500*1300*2300mm;

2.Straightening machine

Roller diameter:100mm; Motor type:frequency; Number of the roller:11; Motor power:7.5kw; Overall size:1600*2300*1200mm;

3.Hydraulic punching and shearing machine

Cutting pressure:180T; Hydraulic motor power:7.5kw; Overall size:1600*1300*2000mm;

4.Feeding machine

Motor power:4kw; Overall size:3700*1800*1300mm;

5.Forming machine

Roller diameter: 80mm; Main motor power: 55kw; Overall size: 8600*3200*1400mm;

6.Collecting table

Overall size: 4500*500*730mm;

7.Main reducer model: ZQ650;

8.Forming mould material: GCr15;

9.Material of the punching head: T10; Material of shearing mould: Cr12;

10.Needed space of the production line(L*W*H): 26000*3700*2500mm;

11.Weight of full production line: 35T;

12.Total speed: 12m/s;

13.Workers required: 3 workers;

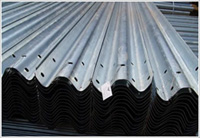

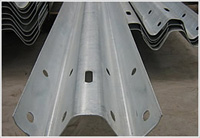

Finished guardrail:

Packed W-beam guardrails Steel guardrails Two waves guardrail

W-beam guardrails W-beam guardrails on highway W-beam highway guardrails

Guardrail roll forming line

Decoiler of guardrail roll forming machine

Straightening machine & Hydraulic punching and shearing machine

Feeding machine of W-beam guardrail forming machine

Guardrail roller

Roll forming part

W-beam guardrails are cost-effective longitudinal highway barriers designed to reduce the severity of run-off-road (ROR) collisions, prevent vehicular impact with roadside objects, and lessen the likelihood of vehicle overturning.

W-beam highway guardrails are the most common crash barrier used on Chinese highways due to their high effectiveness and inexpensive production costs.

Layout of guardrail rollformer:

Roll forming process for W-beam guardrail:

Two-head decoiler----11 roller straightening machine-----four pillar hydraulic punching & shearing machine----feeding mahine----12 passages forming machine----recoiler----collecting table----electrical cabinet

Technical parameters of two waves guardrail roll forming line:

1.Two head decoiler

Loading weight: 10T; Inner diameter: 550mm; Motor power: 7.5kw; Overall dimension: 2500*1300*2300mm;

2.Straightening machine

Roller diameter:100mm; Motor type:frequency; Number of the roller:11; Motor power:7.5kw; Overall size:1600*2300*1200mm;

3.Hydraulic punching and shearing machine

Cutting pressure:180T; Hydraulic motor power:7.5kw; Overall size:1600*1300*2000mm;

4.Feeding machine

Motor power:4kw; Overall size:3700*1800*1300mm;

5.Forming machine

Roller diameter: 80mm; Main motor power: 55kw; Overall size: 8600*3200*1400mm;

6.Collecting table

Overall size: 4500*500*730mm;

7.Main reducer model: ZQ650;

8.Forming mould material: GCr15;

9.Material of the punching head: T10; Material of shearing mould: Cr12;

10.Needed space of the production line(L*W*H): 26000*3700*2500mm;

11.Weight of full production line: 35T;

12.Total speed: 12m/s;

13.Workers required: 3 workers;

Finished guardrail:

Packed W-beam guardrails Steel guardrails Two waves guardrail

W-beam guardrails W-beam guardrails on highway W-beam highway guardrails