Shutter roll forming machine

Advantages:

Shutter roll forming machine

Shutter rollformer

Shutter forming machine

Shutter forming machinery

Control cabinet for shutter roll forming machine

Shutter

Shutter

Shutter

Low maintain cost

High accuracy

Stable running

Low energy cost

Main parameter:

Operation |

Full auto |

Material |

steel plate |

Power source |

AC380/50Hz |

| Roller QTY |

12 groups |

roll axle neck |

40 |

Product width (mm) |

Accordingly to the drawing |

Working speed |

0-12m/min |

Cutting method |

Hydraulic cut |

Cutter material

|

Cr12mov |

Weight |

About 2t |

Machine size (mm) |

5500*900*1500 |

Roller material |

45#steel, quenching and accuracy lathe work |

Press roller material |

Bearing steel vacuum quenching, CNC lathe work |

Board |

14mm thickness steel |

Material thickness |

0.6—1.2mm |

Motor power (kw) |

4KW |

Hydraulic system power |

3.5KW |

Transmission method |

High strength chain transmit |

Working condition:

1. Flat ground

2. Hoist crane (at least 5T)

3. Temperature: more than -14 degress

4. Space for store the material

5. Space for store the products

6. Path for the car in and out

7. Space for the production line: 27*4m

8. Operator: 3men, for operate and handler

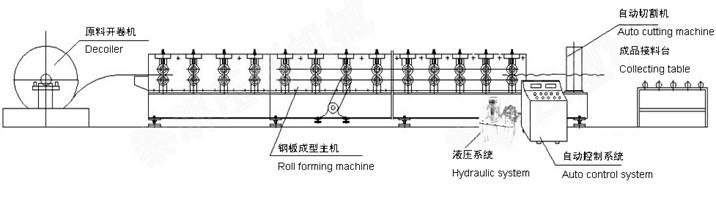

Components:

Decoiler

material guiding table

Roll forming machine

Hydraulic station

Control system (DLTA)

High accuracy auto-length system

Transmission system cover

Finished product collecting table