Roof ridge cap roll forming machine

Description of ridge cap forming machine:

This product is widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product. It has advantage of pretty appearance, durable using and so on. It is producted continuously as roll forming machine instead using bending machine to make angel tile saving human resources, lower labor cost. This machine is composed of automatic discharge table, feed leading table, main forming machine, cutting device, hydraulic station and computer control system. Optional system are normal uncoiler and hydraulic uncoiler.

Process flow:

Uncoiler—Roll forming machine—Computer control system—Hydraulic control syste-Hydraulic cutting—Run out table

Technical parameters:

Material: colored sheet ,galvanized sheet or according to customer’s requirement;

Thickness: 0.4-0.8mm

Width of material: 472mm

Forming steps: 14

Overall dimension: about 6200*1200*1400mm

Motor power: 5.5kw

Output: 2-3m/min

Roller diameter: 70mm

Machine weight: about 2.5T

Detailed description of angle tile roll forming machine:

1. Uncoiler(without motion): To load 5 ton color steel coil and feed material for forming machine, inner diameter 500-508mm

2. Feeding platform: put the raw material on platform , it can guarantee that the products are neat, parallel and everything is uniformity.

3. Main forming machine: In order to keep the product shape and precision, our machine adopts welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard planting, heat treatment and galvanization treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Rolling galvanization thickness:0.05 mm .Rolling material: forging steel 45#.

4. Mould former: This part adopts the exclusive stamping molds (two sets in total) The upper mold’s movement stamps the target material. The molds are neat in surface and precise in dimension and angle. The stamping depth can be adjusted according to need, material of the mold: Cr40, mold is heat-treated.

5. Hydraulic cutting system: It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade :Gcr12, Number of the cutting tool : two pieces.

6. Computer control cabinet: It adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Transducer: the use of it is to make the length more precise and the main machine more stable while processing. Processing precision : within 1.00mm It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. The seller should provide Chinese and English language screen.

7. Counter: One counter gauges length, pulses, and decides length.

8. Standard components: Chain 1 pcs, Hydraulic oil pipes: 2 pcs, electromagnetism valves 1 pcs. limit switch:2 pcs

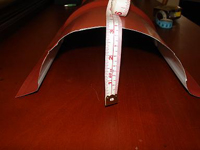

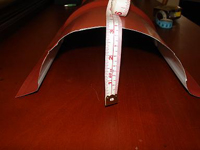

Finished roof ridge cap:

Roll formed angle tileRoll formed roof ridge capRoof ridge cap

Main forming machine of roof ridge cap forming machine

Ridge cap roll forming machine

Roof ridge cap forming machine

Forming roller

Forming mould

Ridge cap roll forming machine

Main forming machine of roof ridge cap forming machine

Ridge cap roll forming machine

Roof ridge cap forming machine

Forming roller

Forming mould

Ridge cap roll forming machine

Description of ridge cap forming machine:

This product is widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product. It has advantage of pretty appearance, durable using and so on. It is producted continuously as roll forming machine instead using bending machine to make angel tile saving human resources, lower labor cost. This machine is composed of automatic discharge table, feed leading table, main forming machine, cutting device, hydraulic station and computer control system. Optional system are normal uncoiler and hydraulic uncoiler.

Process flow:

Uncoiler—Roll forming machine—Computer control system—Hydraulic control syste-Hydraulic cutting—Run out table

Technical parameters:

Material: colored sheet ,galvanized sheet or according to customer’s requirement;

Thickness: 0.4-0.8mm

Width of material: 472mm

Forming steps: 14

Overall dimension: about 6200*1200*1400mm

Motor power: 5.5kw

Output: 2-3m/min

Roller diameter: 70mm

Machine weight: about 2.5T

Detailed description of angle tile roll forming machine:

1. Uncoiler(without motion): To load 5 ton color steel coil and feed material for forming machine, inner diameter 500-508mm

2. Feeding platform: put the raw material on platform , it can guarantee that the products are neat, parallel and everything is uniformity.

3. Main forming machine: In order to keep the product shape and precision, our machine adopts welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard planting, heat treatment and galvanization treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Rolling galvanization thickness:0.05 mm .Rolling material: forging steel 45#.

4. Mould former: This part adopts the exclusive stamping molds (two sets in total) The upper mold’s movement stamps the target material. The molds are neat in surface and precise in dimension and angle. The stamping depth can be adjusted according to need, material of the mold: Cr40, mold is heat-treated.

5. Hydraulic cutting system: It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade :Gcr12, Number of the cutting tool : two pieces.

6. Computer control cabinet: It adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Transducer: the use of it is to make the length more precise and the main machine more stable while processing. Processing precision : within 1.00mm It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. The seller should provide Chinese and English language screen.

7. Counter: One counter gauges length, pulses, and decides length.

8. Standard components: Chain 1 pcs, Hydraulic oil pipes: 2 pcs, electromagnetism valves 1 pcs. limit switch:2 pcs

Finished roof ridge cap:

Roll formed angle tileRoll formed roof ridge capRoof ridge cap