Steel profile roll forming machine

Technical process:

Technical process:

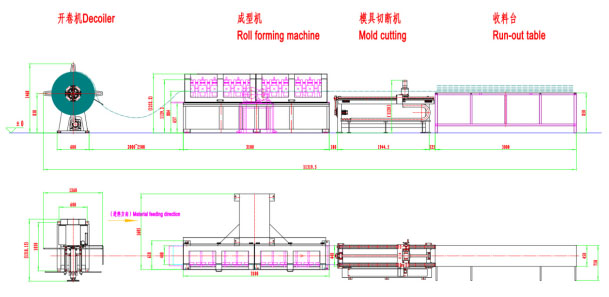

Manial de-coiler→ Feed with guide→ Roll forming→ Mold cutting with fixed length→ Run-out table→ PLC control

Typical profile drawing:

Flow chart:

Specifications:

Material: galvanized steel sheet

Sheet thickness: 0.5-0.9mm

Input width: 38mm

Number of stations: 16 stations

Working speed: 15-19m/min

Structure: Wall panel

Way of drive: by chain

Electric Source: 380V, 50HZ, 3 phase, Also can satisfy customer’s require

Roll material: Gcr15 steel, heat treatment;

Main shaft material: 45# steel, quenching and tempering treatment;

Chain: material 45# steel, high-frequency hardening, pitch: 31.8; number of teeth: 10;

Main motor power: 5.5KW;

Cutting: use mold cutting

Electric control system: Siemens system

Machine size(L*W*H): 12000mm×1600mm×1500mm;

Total machine weight: about 4 tons.

Roll forming machine

Cold roll forming machine

Roll forming line

Steel roll forming machine

Steel metal roll forming machine

Cold roll forming line

Cold roll forming machine

Steel roll forming machine

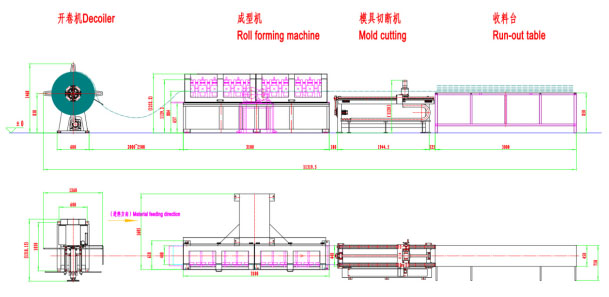

Manial de-coiler→ Feed with guide→ Roll forming→ Mold cutting with fixed length→ Run-out table→ PLC control

Typical profile drawing:

Flow chart:

Specifications:

Material: galvanized steel sheet

Sheet thickness: 0.5-0.9mm

Input width: 38mm

Number of stations: 16 stations

Working speed: 15-19m/min

Structure: Wall panel

Way of drive: by chain

Electric Source: 380V, 50HZ, 3 phase, Also can satisfy customer’s require

Roll material: Gcr15 steel, heat treatment;

Main shaft material: 45# steel, quenching and tempering treatment;

Chain: material 45# steel, high-frequency hardening, pitch: 31.8; number of teeth: 10;

Main motor power: 5.5KW;

Cutting: use mold cutting

Electric control system: Siemens system

Machine size(L*W*H): 12000mm×1600mm×1500mm;

Total machine weight: about 4 tons.